You are here:

Home » Products – Tin stripper

Tin-Stripper

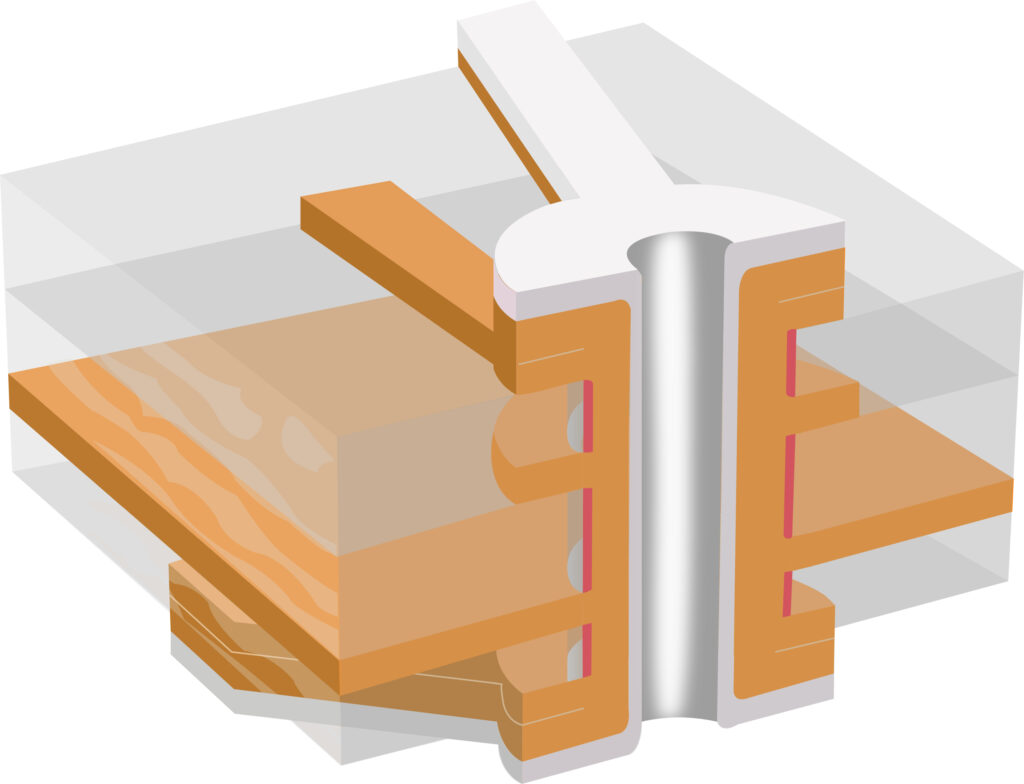

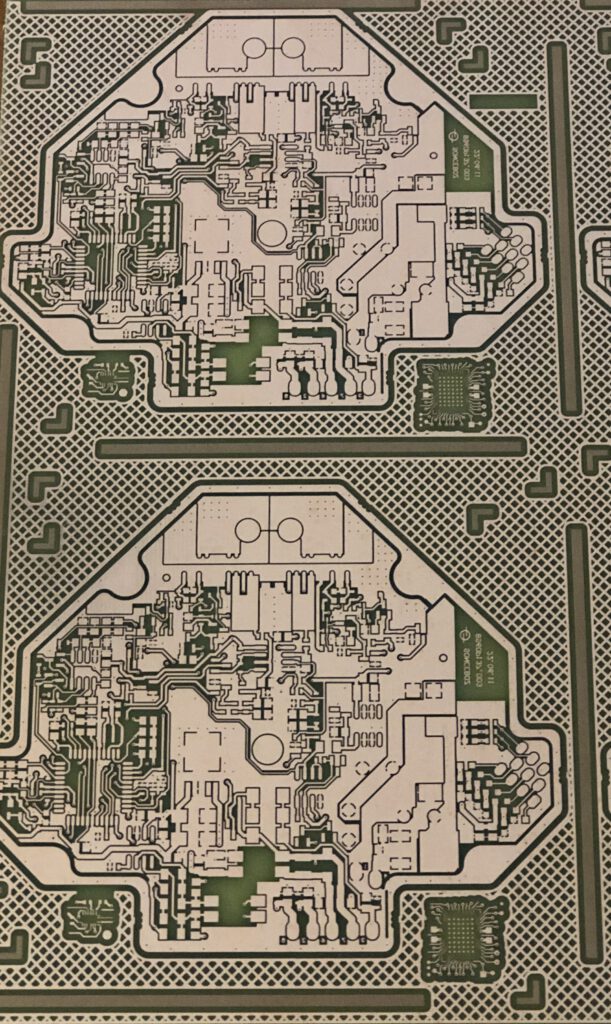

Vor dem Zinn strippen:

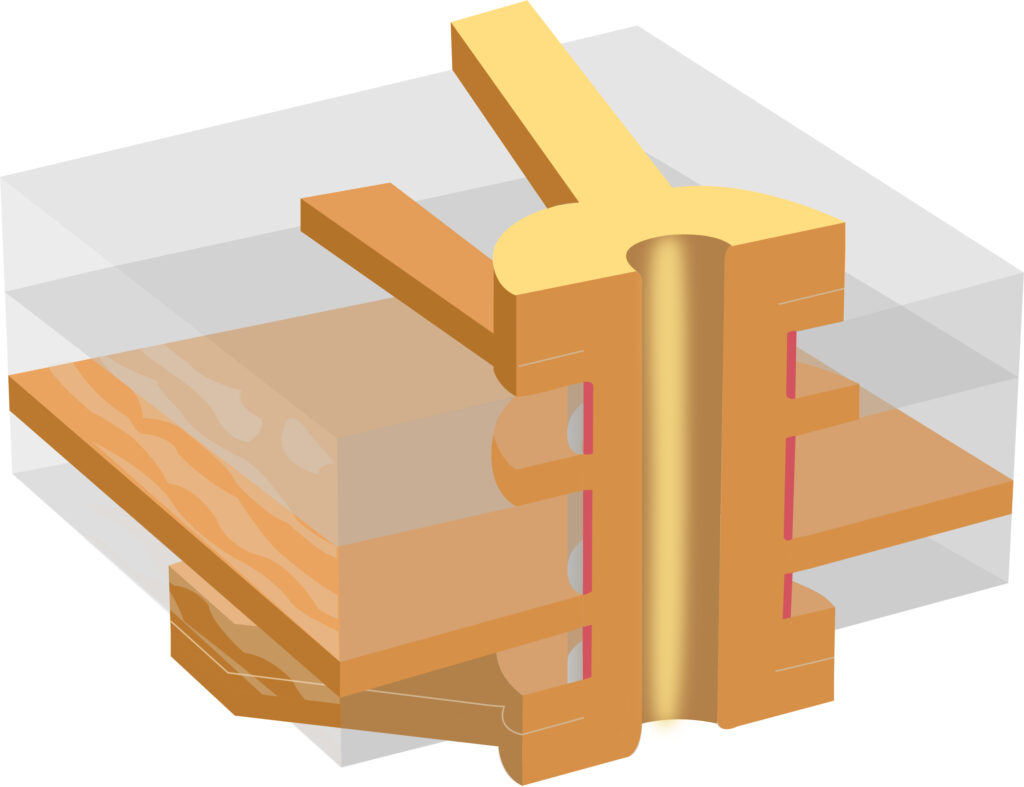

Nach dem Zinn strippen:

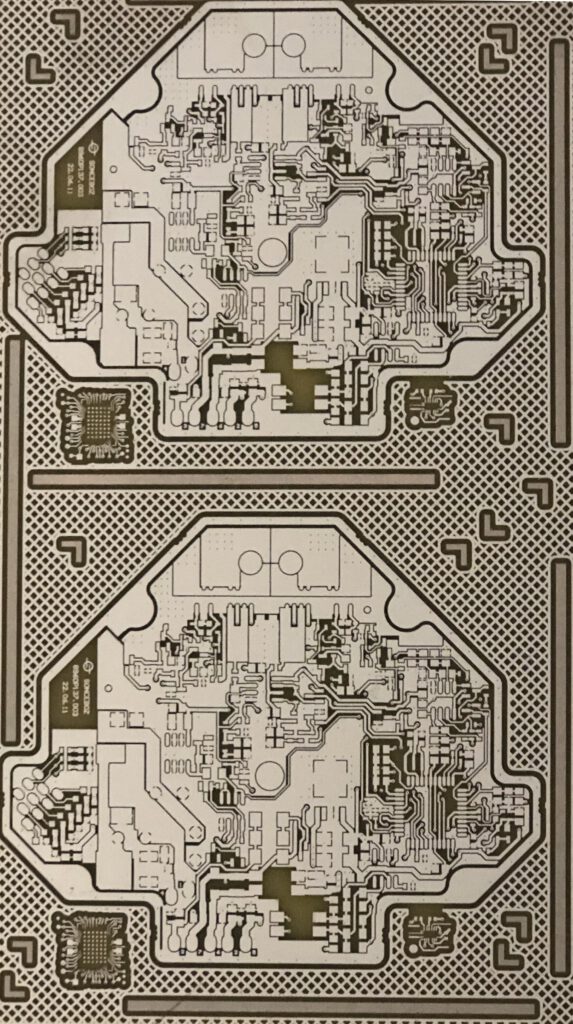

BECE SINSTA-STRIP AT 25 – Efficient single-stage stripper for clean copper surfaces

BECE SINSTA-STRIP AT 25 is a nitric acid-based one-step stripper specifically designed for the removal of electroplated tin and tin/lead layers from copper surfaces. This powerful product offers a fast and reliable solution for the demanding requirements of PCB processing.

Outstanding Features

- Fast Stripping Speed: Removes tin and tin/lead at a rate of 5–8 µm/minute, even with high metal loads.

- High Capacity: Handles metal loads with densities up to 1.40 g/cm³ without losing effectiveness.

- Anti-Sludge Technology: Special additives reliably prevent sludging, even at high metal concentrations.

- Copper Protection: Inhibitors protect copper surfaces from attack without affecting the stripping speed.

- Perfect Surface Quality: Additives and integrated tarnish protection prevent oxidation, leaving uniformly shiny copper surfaces.

- Effluent-Friendly Process: Free from peroxides, fluorides, and ammonium, significantly simplifying wastewater treatment.

- Optimized for Horizontal Systems: Ideal for horizontal conveyor systems with 2.5–3.5 bar spray pressure.

- Versatile Application: Can also be used as an immersion stripper to meet diverse process requirements.

BECE SINSTA-STRIP AT 25 is a reliable and fast tin stripper designed to remove tin and tin/lead layers efficiently. Combining outstanding performance with excellent surface quality, it ensures easy handling and seamless process integration.

KEY PRODUCT ADVANTAGES:

- High stripping speed (approximately 15 µm/minute)

- High metal absorption capacity (>200 g/l)

- Single-stage system

- No sludge formation and no clogged spray nozzles

- Reduced maintenance and downtimes

- Extremely low attack on copper

- Easy wastewater neutralization as it contains no ammonium

Visualization of Before and After: