Sie sind hier:

Home » Products – Pre-cleaning Photoresist

Pre-Cleaning microetching solution for photoresist

BECE MiCuETCH 2103 –Microetching solution for dry film resist solder mask and final surfaces.

BECE MiCuETCH 2103 is an advanced acidic micro-etching solution specifically developed for pre-cleaning PCBs and copper surfaces. It meets the highest demands of fine-line technology, where conventional methods like brushing or sodium persulfate fall short.

Outstanding Features

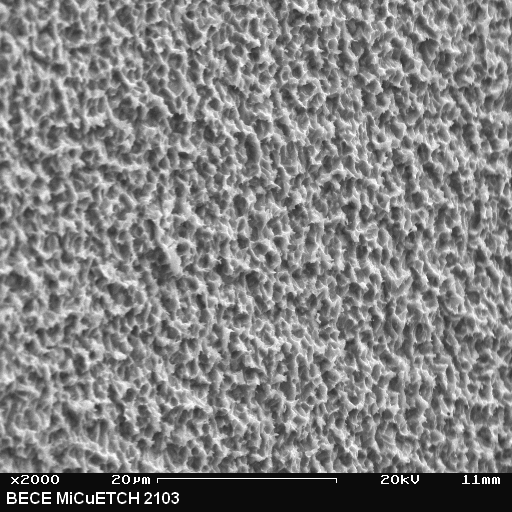

- Fine-Crystalline Surface Topography: Produces a uniform, controlled roughening of the copper surface for optimal adhesion through mechanical interlocking.

- Enhanced Adhesion: Perfect for subsequent processes such as:

- Laminating liquid and dry film resist

- Solder mask coating

- Hot tinning

- High Efficiency: Controlled copper etch rates of 0.8–2.0 µm and high copper absorption capacity of up to 40 g/l.

- Simple Dosing: Replenishment requires only BECE MiCuETCH 2103—no additional chemicals needed.

- Compatible and Flexible: Suitable for horizontal spray systems without modifications.

- Gentle on Materials: Does not attack stainless steel or titanium, extending equipment lifespan.

- Reliable Performance: Ensures uniform results for perfect adhesion and maximum precision.

Applications

- PCB Manufacturing: Ideal for pre-treatment of copper surfaces in modern fine-line applications.

- Fine Structures: Meets the highest standards for adhesion-secure coatings.

KEY PRODUCT ADVANTAGES:

- Creates a highly roughened copper surface topography for optimal adhesion values

- Ideal for photoresist coating preparation

- Easy and straightforward handling and replenishment

- High copper absorption capacity of up to 40 g/l

- Contains no volatile substances

- No expensive machine modifications required; existing equipment can be easily retrofitted as it is non-corrosive to stainless steel and titanium

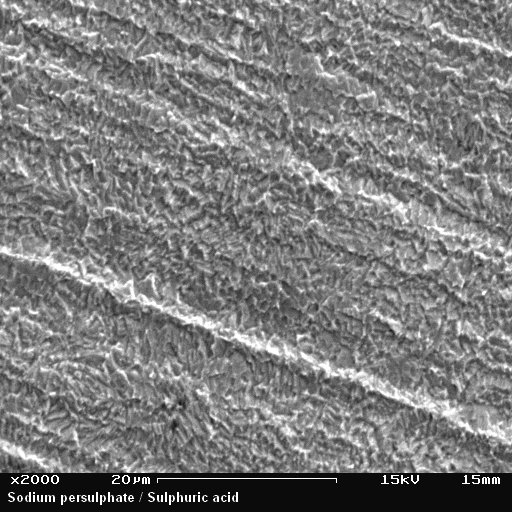

Copper Surface Topography with Sodium Persulfate:

Smooth structures hinder adhesion between materials.

Copper Surface Topography with BECE MiCuETCH 2103:

The knobby copper topography achieves excellent adhesion values through a “push-button” effect.