You are here:

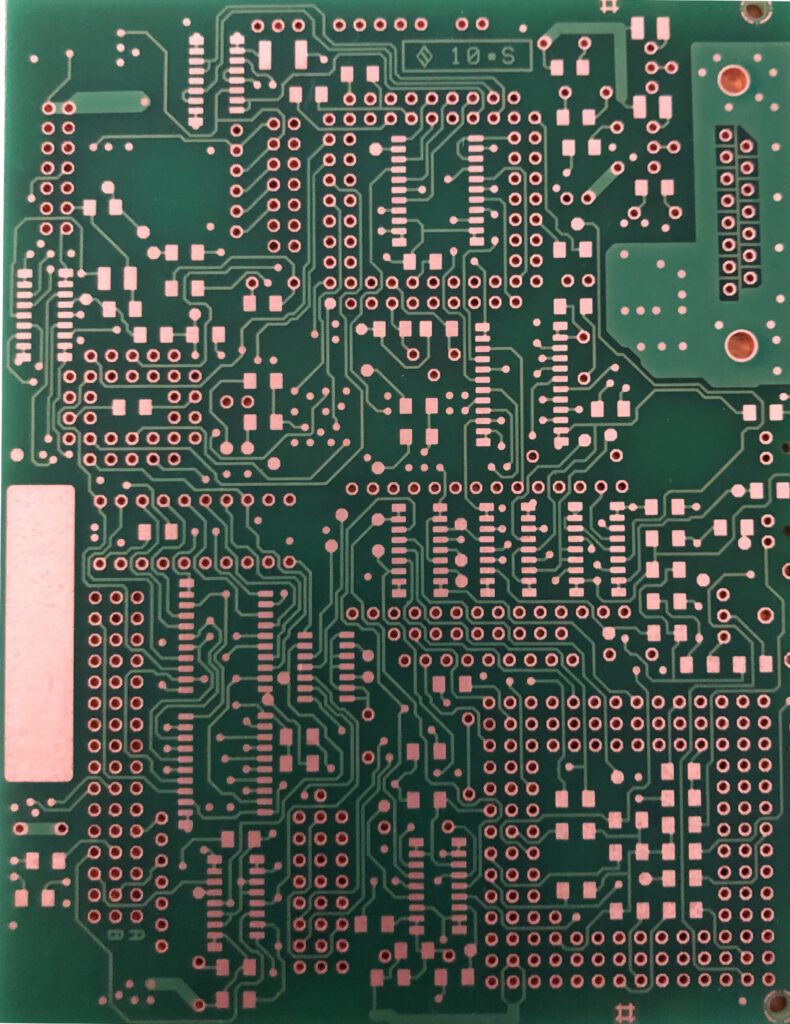

Home » Products – Microetch solder mask inner layer adhesion

Pre-cleaning microetching solution for solder mask coating & inner layer adhesion

BECE MiCuBOND 3108 – Microetch solution for optimal copper adhesion

BECE MiCuBOND 3108 is a weakly acidic micro-etching solution specifically designed for the pre-cleaning of PCBs and copper surfaces. It meets the highest standards of modern fine-line technology, ensuring maximum adhesion for demanding applications with its innovative technology.

Outstanding Features

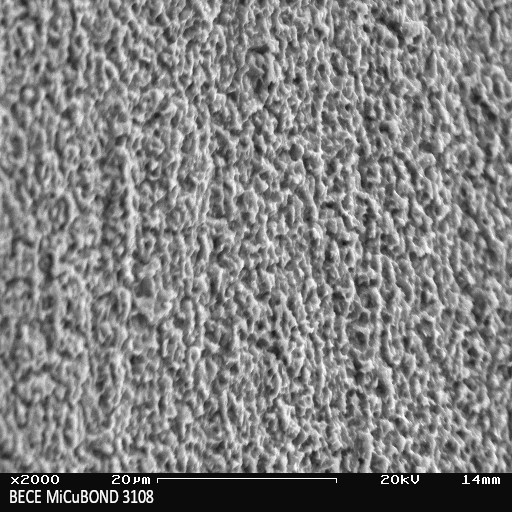

- Grain Boundary Etching in Z-Direction: Special chloride compounds create a fine-crystalline, uniform surface topography, enabling excellent adhesion through interlocking (push-button effect).

- Optimized Copper Adhesion: Particularly suitable for:

- Pressing of inner layers

- Solder mask coating

- Laminating liquid and dry film resists (L/S < 100 µm)

- Pre-cleaning of copper foils and microvias

- Precise Control: Copper etch rates of 0.6–1.5 µm with a high absorption capacity of up to 35 g/l.

- Efficient Application: Suitable for horizontal spray systems, ideally fully automated in a feed & bleed process.

- Easy Handling: Ready-to-use starter solution (S) and replenisher solution (R) enable straightforward process management without additional chemicals.

Applications

- PCB Manufacturing: Optimized adhesion for fine-line structures and demanding coating processes.

- Microvias and RCC Copper: Precise pre-cleaning for cutting-edge PCB technology.

KEY PRODUCT ADVANTAGES:

- Erzeugt eine super aufgeraute Kupferoberflächentopographie für bestmögliche Haftwerte

- Ideal vor der Lötstopplackbeschichtung oder Foto-Resist-Beschichtung

- Ideal als Ersatzverfahren vor dem Verpressen der Innenlagen von Multilayer

- Verhindert Unterwanderungen bei der Beschichtung mit Endoberflächen (z. B. ENIG)

- Leichte und einfache Handhabung und Ergänzung

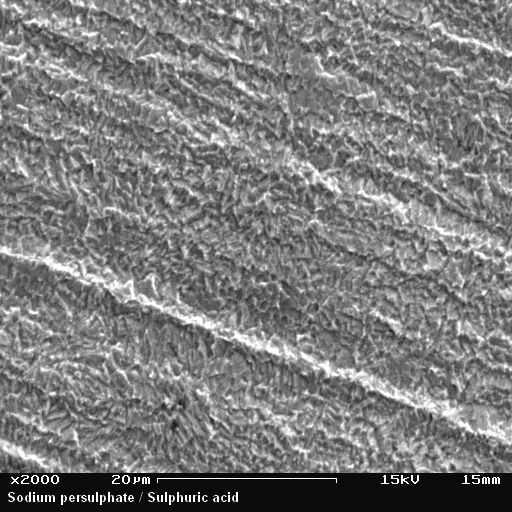

Copper Surface Topography with Sodium Persulfate:

Smooth structures make adhesion between materials more difficult.

Copper Surface Topography with BECE MiCuBOND 3108:

The knobby copper topography provides excellent adhesion values through a “push-button” effect.