You are here:

Home » Products – Microetch pre-cleaning

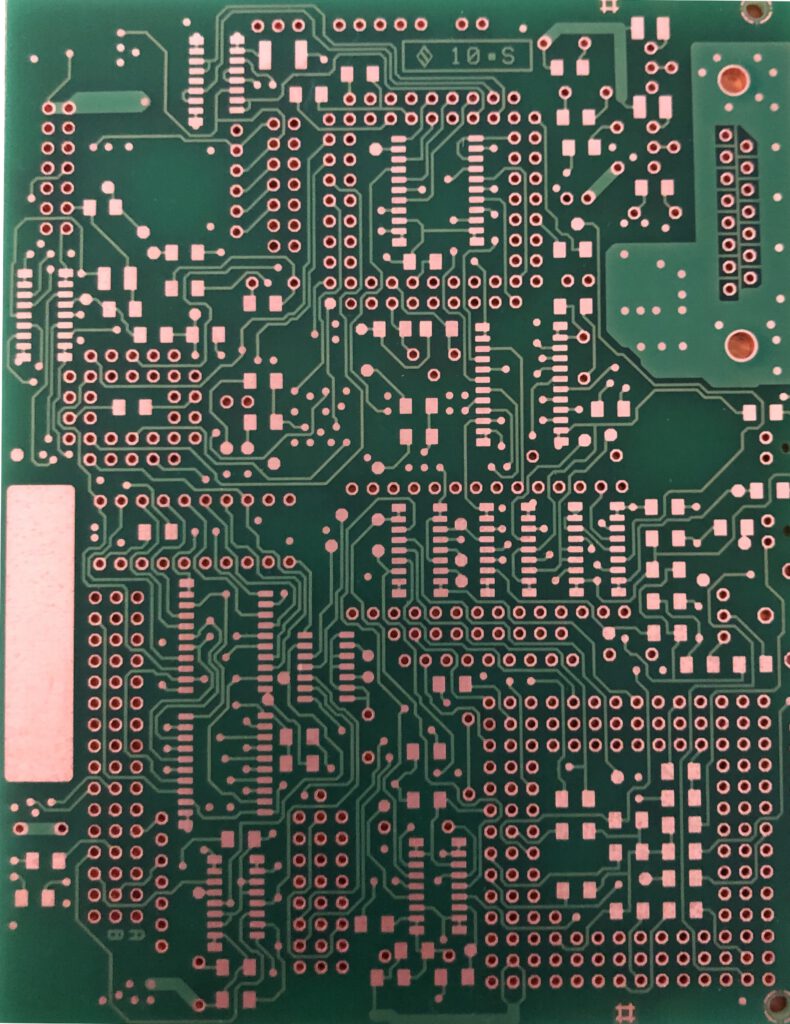

Microetch solution for pre-cleaning of copper surfaces

BECE MiCuETCH 1442 - Effective and reliable microetching solution for PCBs

BECE MiCuETCH 1442 is an acidic micro-etching solution based on stabilized hydrogen peroxide and sulfuric acid. It is specifically designed for the effective pre-cleaning of PCBs and copper surfaces, ensuring optimal preparation for subsequent production steps.

Applications

- Ideal for pre-cleaning prior to processes such as through-hole plating, circuit pattern formation, and surface coating.

- Suitable wherever clean and active copper surfaces are required.

Outstanding Features

- Excellent Stabilization: Hydrogen peroxide remains exceptionally stable, providing uniform and controlled copper etch rates of 0.8–1.8 µm.

- High Copper Absorption: Capable of absorbing up to 40 g/l of copper while maintaining effectiveness.

- Efficient Dosing: Regenerable and compatible with automatic dosing systems in feed & bleed operations.

Flexible Application

BECE MiCuETCH 1442 is highly versatile and suitable for use in horizontal spray systems, vertical immersion tanks, or electroplating machines.

KEY PRODUCT ADVANTAGES:

- Clean, active copper surfaces for the highest quality standards

- Extremely effective stabilization of hydrogen peroxide

- Uniform copper etch rates of approximately 1.0–1.5 µm/minute

- Copper absorption up to 40 g/l

- Very simple and easy handling and replenishment

- Consistent results across a wide operating range

BECE MiCuETCH 1542

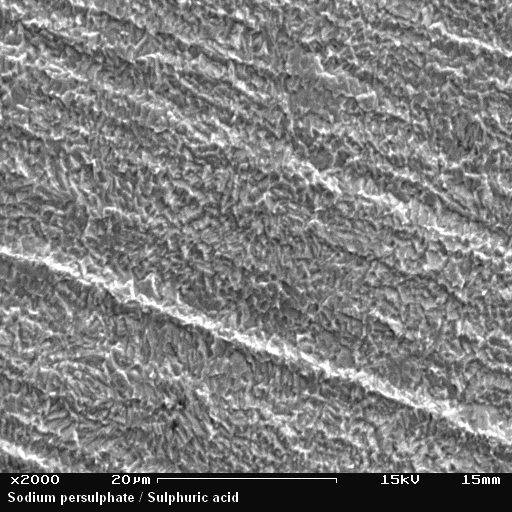

BECE MiCuETCH 1542 is a highly effective acidic micro-etching solution specifically designed for the pre-cleaning of PCBs and copper surfaces. It ensures optimal preparation for subsequent process steps and delivers clean, active surfaces.

With its stable persulfate/sulfuric acid-based formulation, BECE MiCuETCH 1542 provides reliable results and is easy to handle—an ideal choice for cost-effective production needs.

Applications

- Versatile and ideal for pre-cleaning before through-hole plating, circuit pattern formation, or final surface coating.

- Suitable wherever clean and active copper surfaces are required.

Outstanding Features

- Precise Etch Rates: Controlled and uniform copper etch rates between 0.8 and 1.5 µm, depending on the solution concentration.

- High Copper Absorption: Efficiently absorbs up to 35 g/l of copper.

- Sustainable and Regenerable: Compatible with automatic dosing systems for continuous use in feed & bleed operations.

Flexibility in Application

- Suitable for horizontal spray systems, vertical immersion tanks, and electroplating machines.

- Adaptable to various production processes for maximum efficiency.

KEY PRODUCT ADVANTAGES:

- Uniform copper etch rates of approximately 1 µm/minute

- Copper absorption up to 35 g/l

- Very simple and easy handling and replenishment

BECE DEGRAETCH 2084 - Microetching cleaner for perfect copper surfaces

BECE DEGRAETCH 2084 is an acidic micro-etching solution specifically designed for the pre-cleaning of PCBs and copper surfaces. By combining the degreasing and etching processes in a single step, it offers exceptional efficiency and cost-effectiveness.

Applications

Perfect for all pre-cleaning processes, including:

- Through-hole plating

- Circuit pattern formation

- Solder mask coating

- Final surface coating

Ideal wherever clean and active copper surfaces are required.

Outstanding Benefits

- Two Processes in One Step: Combines degreasing and etching in a single operation, saving:

- Machine costs

- Processing and labor time

- Rinse water usage and overall costs

- Precise Etch Rates: Controlled copper etch rates of 0.2–1.6 µm.

- High Copper Absorption: Capacity of up to 40 g/l, making it ideal for demanding processes.

Highly Efficient Cleaning

- Reliably removes thin oxide layers and handling residues, such as fingerprints.

- Reduces surface tension for excellent wetting properties in subsequent processes.

Stable and Durable Formulation

- Sulfuric Acid and Stabilized Hydrogen Peroxide: Minimizes peroxide decomposition for extended usability.

- Additional Stable Surfactants: Enhance cleaning properties and improve performance in subsequent processes.

Flexible Use

- Ideal for horizontal spray systems at temperatures above 30 °C.

- Also suitable for vertical immersion cleaning in appropriate systems.

KEY PRODUCT ADVANTAGES:

- 2 in 1: Combined microetching and degreasing solution

- Effectively removes inorganic and organic contaminants

- Creates a highly active copper surface with minimal copper removal, resulting in excellent wetting properties

- Includes stabilized hydrogen peroxide, significantly slowing down its decomposition