You are here:

Home » Products – Immersion tin

Immersion tin process

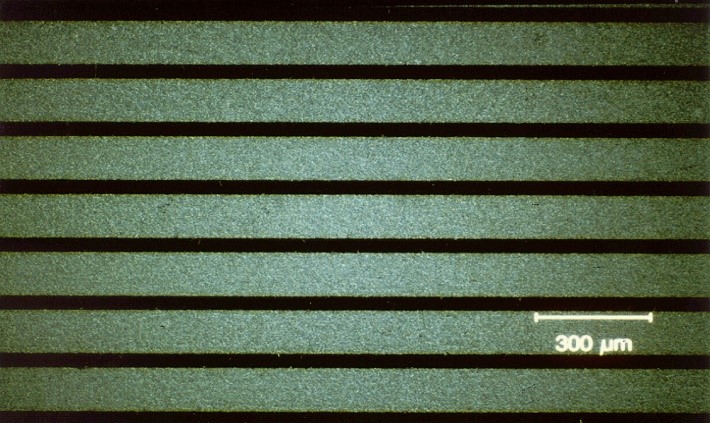

Fine-Line application – Conductor spacing 50µm.

BECE STANOSIT-EC 2002 – Precise and reliable tin deposition as final surface.

The BECE STANOSIT-EC 2002 process is a powerful immersion tin plating system specifically designed to meet the demands of modern PCB manufacturing. With its high reliability and user-friendly operation, it provides an optimal solution for immersion tin deposition on copper surfaces.

Outstanding Features

- Uniform Tin Layers: Produces flat, fine-grained, and dense tin layers on even the smallest copper surfaces, with a layer thickness of 0.8–1.2 µm and excellent solderability-compatible with Pb-free and Sn/Pb solders.

- Bridge Prevention: Immersion tin deposition effectively minimizes the risk of tin bridges between individual pads, reliably preventing short circuits.

- Gentle Processing: The low process temperature of only 70 °C reduces thermal stress and protects the PCBs.

Efficient Process Management

- Predip Solution: BECE STANOSIT-EC 2002 Predip prevents contamination of the main tin bath and enhances deposition and surface results through light pre-tinning at room temperature.

- Easy Operation: Ready-to-use solutions and a single replenisher for both the predip and the main tin bath make process control quick and straightforward.

- Extended Bath Life: Special additives minimize tin-IV formation, increasing the process stability and efficiency.

Copper Control for Optimal Results

- During tin deposition, approximately 1.1 g of copper dissolves for every 1.0 g of tin deposited.

- When the copper concentration reaches 7 g/l, the tin layer properties may be affected.

- Copper can be efficiently removed as a complex by cooling to room temperature, extending the bath life.

Versatile Application

The BECE STANOSIT-EC 2002 process is suitable for use in both vertical dip systems and horizontal flow systems, making it a versatile solution for immersion tin deposition.

KEY PRODUCT ADVANTAGES

Properties of the tin layer:

- Flat, uniformly thick, and fine-crystalline layer

- Layer thickness depending on immersion time: 0.3 - 1.2 µm

- No tin bridges, meaning no short circuits

- Solderable even after "aging" for 4 hours at 155 °C

- High surface resistance of the coated PCB

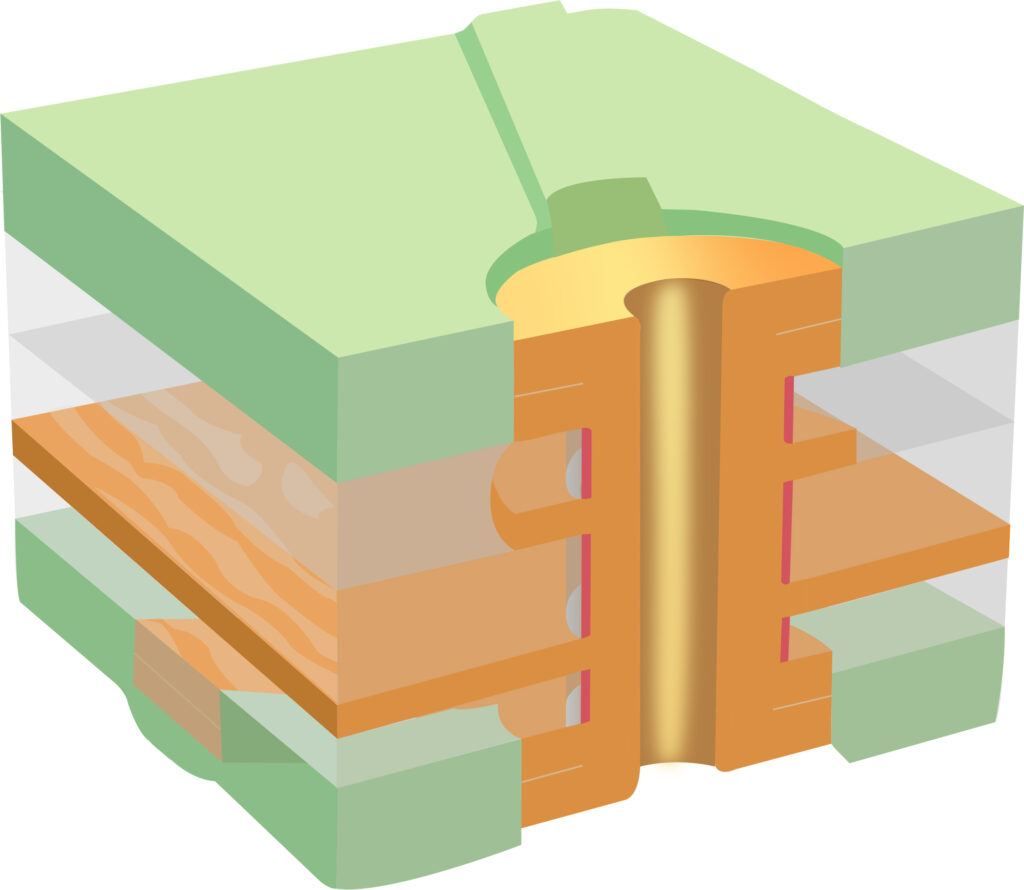

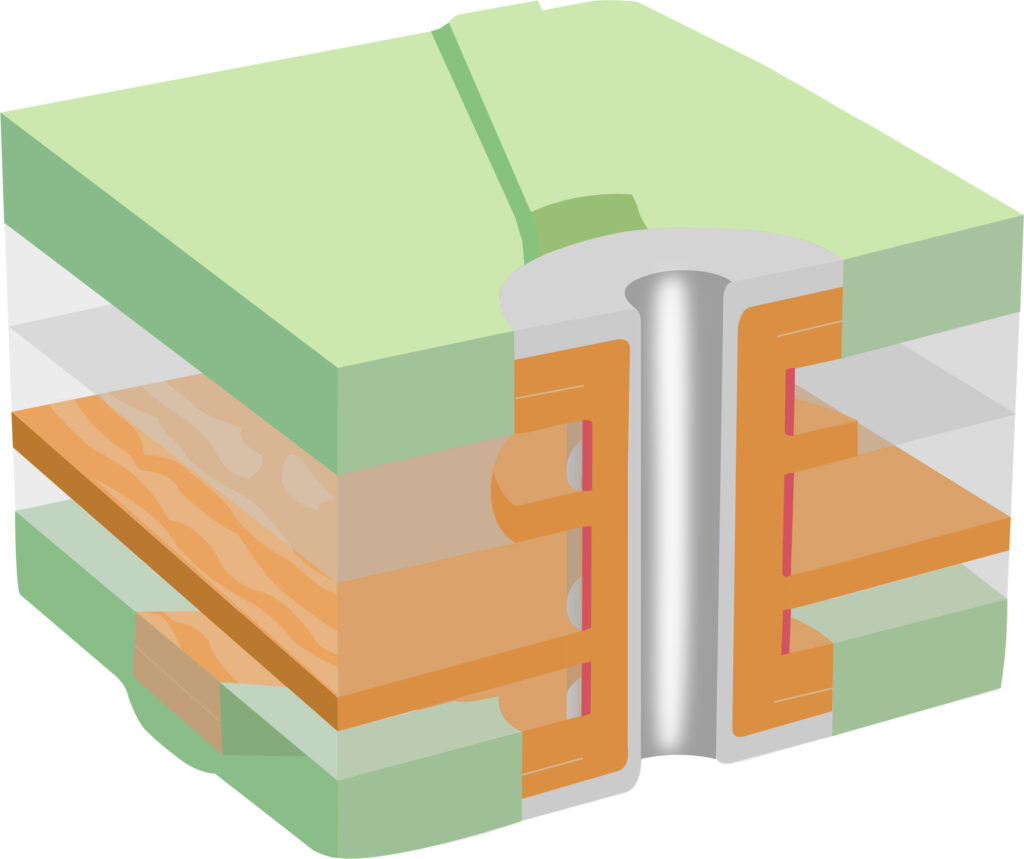

- Suitable for press-fit technology.

- Ideal for fine-pitch SMD technology

Properties of the tin layers:

- Simple process management

- Copper absorption up to 7 g/l possible without quality loss

- Extension of bath life possible through copper depletion

- Suitable for immersion processes (vertical) and conveyor processes (horizontal)

Before and After Visualization: