You are here:

Home » Products – HASL-Flux for hot-air-leveling

HASL-Flux, vertical und horizontale hot-air-leveling

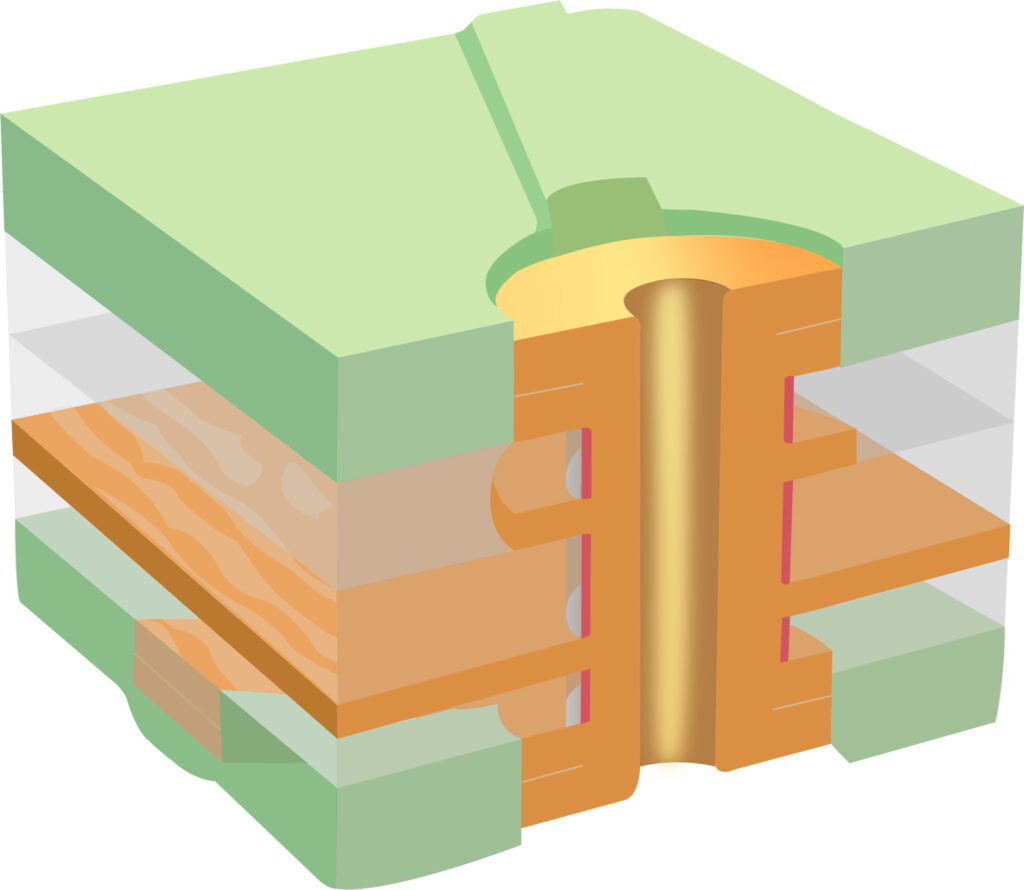

Final surface, tinned with BECE HAL-FLUX 7059:

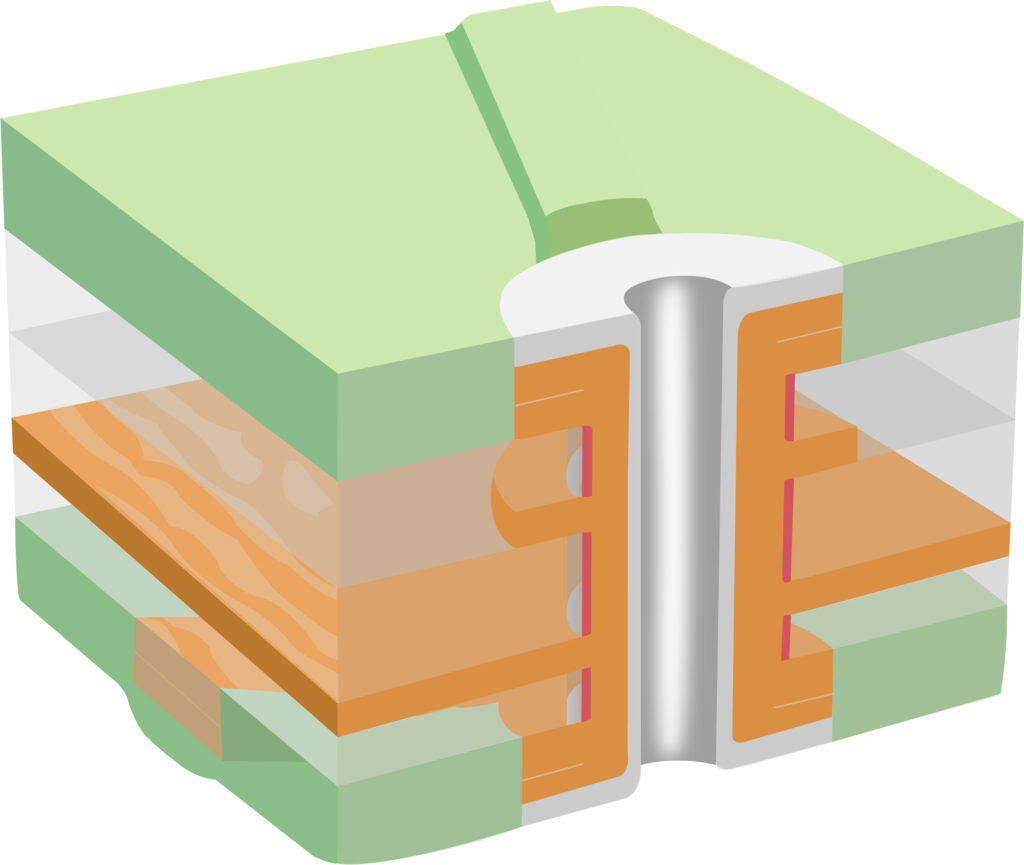

Final surface, tinned with a competitor product:

BECE HAL-FLUX 7059 - Flux for perfect hot-air-leveling results

BECE HAL-FLUX 7059 is specifically developed for use in vertical hot-air-leveling systems, delivering exceptional results as a proven and reliable final surface for PCBs. Its high-temperature resistance makes it ideal for lead-free (Pb-free) and Sn/Pb solders, ensuring outstanding quality in demanding processes.

Thanks to its effective copper activation, BECE HAL-FLUX 7059 removes light oxidation and ensures flawless, uniform tin surfaces. The reduced surface tension enables superior wetting and prevents solder balls or tin streaks from adhering. Even challenging materials like CEM-1 can be tinned without forming tin streaks or whiskers.

Outstanding Features

- Clean and Efficient: Minimizes machine contamination and protects against solder splashes.

- Easy to Clean: Fully water-soluble and easily washable – even with cold water and without foaming.

- Maximum Compatibility: Free from interactions with leading solder masks, ensuring no discoloration or leaching.

- Guaranteed Machine Protection: Hydrochloric acid-free, significantly reducing corrosion of machine parts and solder pots.

BECE HAL-FLUX 7059 is the ultimate solution for high-performance, precise, and reliable hot tinning that meets the most stringent requirements.

KEY PRODUCT ADVANTAGES:

- Excellent wetting and activation properties

- Shiny and uniform tin surfaces, with excellent solder distribution

- Rapid reduction of surface tension

- Efficient removal of light copper oxides

- High temperature resistance, resulting in less smoke and odor nuisance

- No tin streaks or solder balls on the solder mask surface

- Ideal for SMD technology

- No corrosion of the equipment as it is chloride-free

Visualization of Before and After:

BECE HAL-FLUX 3138 & BECE HAL-OIL 3038 – Maximum efficiency for horizontal hot-air-leveling

BECE HAL-FLUX 3138 and BECE HAL-OIL 3038 are specifically designed for horizontal hot-air-levelin systems and deliver outstanding results for PCB soldering. Together, these products ensure superior hot-air-leveling performance, high process stability, and consistently excellent surface quality.

Outstanding Features

- Optimal Copper Activation: Gently removes light oxidation and reduces surface tension for flawless solderability.

- Clean Processes: Prevents the formation of solder balls and tin streaks on solder masks and base materials, ensuring impeccable results.

- Shiny Results: Produces uniform, high-gloss solder surfaces that meet the highest standards.

- Easy Handling: The flux can be completely and easily removed with water after the tinning process.

Additional Benefits of BECE HAL-OIL 3038

- Thermal Resistance: Developed for the demanding requirements of horizontal hot tinning.

- Protection and Lubrication: Lubricates pumps and transport mechanisms when used in recirculation or oil injection systems. The oil film also protects the solder mask from mechanical stress.

- Optimal Synergy: In combination with BECE HAL-FLUX 3138, the cover oil ensures stable and efficient hot tinning.

Exceptional Longevity and Process Stability

The combination of BECE HAL-FLUX 3138 and BECE HAL-OIL 3038 provides impressive service lives of up to 90 hours. This exceptional stability enables continuous and reliable production with consistently high quality.

KEY PRODUCT ADVANTAGES:

- No corrosion of the equipment, as it is chloride-free

- Excellent solder distribution

- Ideal for SMD technology

- Rapid reduction of surface tension

- Excellent solderability and shiny final surfaces

- Maximum process stability and long service life of up to 90 hours

- Very good lubrication of the transport mechanism