You are here:

Home » Products – Desmearing/Etchback

Desmearing-/Etchback-Process

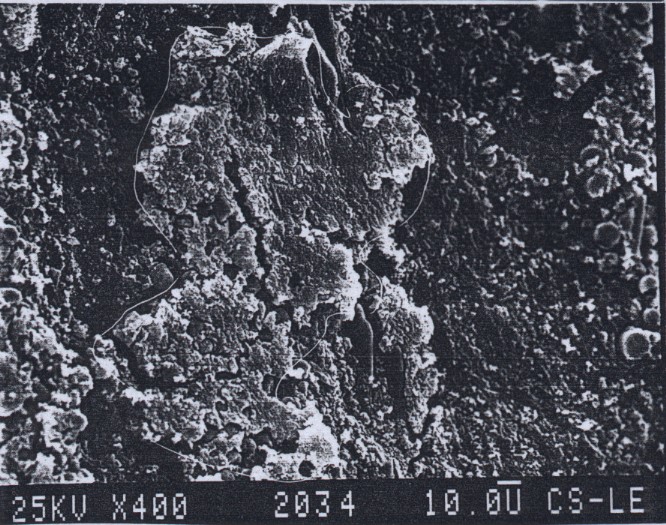

Resin smears after drilling

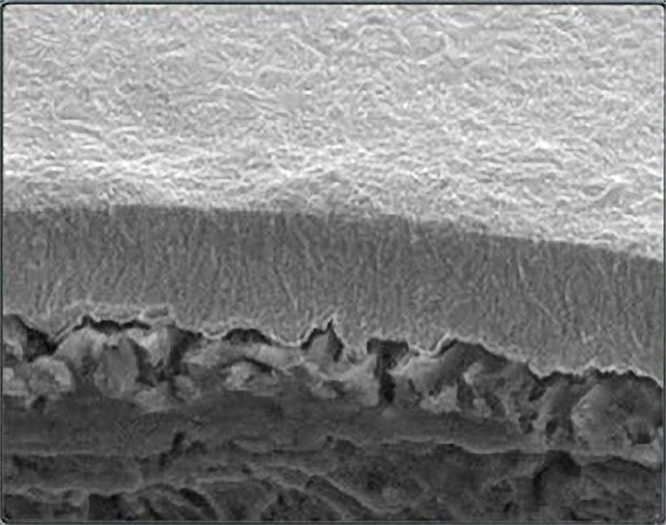

Cleaned and etched-back drill hole wall

BECE MANGASEAR is a desmearing/etchback process that cleans and conditions through-holes by removing resin smears created during the drilling of PCBs and multilayers.

The BECE MANGASEAR process consists of three stages:

- BECE MANGASEAR SW: For swelling the resin smears.

- BECE MANGASEAR DES: For etching back the swollen resin smears.

- BECE MANGASEAR Redcon: For completely removing the resulting manganese dioxide residues.

BECE MANGASEAR SW - Alkaline swellant for the desmearing process

BECE MANGASEAR SW is an alkaline, solvent-based yet water-soluble swellant designed to swell resin smears on inner layers caused by drilling. These smears are then effectively removed in the subsequent etchback process BECE MANGASEAR DES.

BECE MANGASEAR SW can be used in both vertical and horizontal systems.

BECE MANGASEAR DES - Etchback process based on potassium permanganate

BECE MANGASEAR DES is a concentrated, alkaline potassium permanganate etchback process designed to remove the already swollen resin smears from the inner copper layers.

BECE MANGASEAR DES ensures consistent etchback rates through the use of specialized additives BECE MANGASEAR Desmalk and BECE MANGASEAR Desmoxad for correction.

BECE MANGASEAR DES is prepared and regenerated using commercially available potassium permanganate.

BECE MANGASEAR Redcon - Reduction cleaner after the etchback process

BECE MANGASEAR Redcon is an acidic solution that efficiently removes all residues of manganese compounds and manganese dioxide formed during the desmearing process from the PCB surface and hole walls.

BECE MANGASEAR Redcon ensures clean and roughened dielectric surfaces while conditioning the surface for secure palladium uptake, enabling reliable through-hole metallization even on challenging base materials.

KEY PRODUCT ADVANTAGES:

- Optimal cleaning of hole walls by swelling drilling residues and smears

- Reliably removes resin smears from inner layers after drilling

- Irregularities and outgassing on the hole wall are eliminated

- Controlled and uniform etchback rates

- Chemical roughening of the drill hole for optimal adhesion of subsequent through-hole plating

- Efficiently removes all residues of the resulting manganese dioxide

- Prevents the pink-ring effect