You are here:

Home » Products – Flux for wave soldering

Wave soldering

BECE ENViRE FLUX 8305 - Water-based foam and spray flux for PCB assembly.

BECE ENViRE FLUX 8305 – Advanced, Eco-Friendly No-Clean Flux

BECE ENViRE FLUX 8305 is a fully water-based, VOC- and halogen-free no-clean flux, specifically developed for spray and foam applications in PCB assembly. It combines efficiency, environmental sustainability, and versatile applications for modern manufacturing processes.

Powerful Features

- Efficient Cleaning: Effortlessly removes oxide layers with only 3% solid content and protects against reoxidation during the preheating phase.

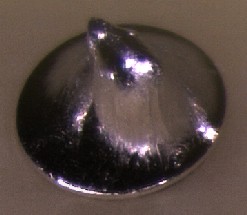

- Excellent Wetting: Reduced surface tension enables fast and reliable soldering, especially with Pb-free solders.

- Safe Against Solder Balls: Special additives effectively prevent solder ball formation, ensuring a smooth surface.

Flexible Applications

- Compatible with Modern Soldering Techniques: Perfect for selective, wave, and automated soldering in SMD/SMT and THT processes.

- Broad Material Compatibility: Suitable for Pb-free and Pb/Sn solders as well as finishes like HAL, chemical Ni/Au, chemical Sn, and OSP.

- For Multilayer and Double-Sided PCBs: No interference with common solder masks from leading manufacturers.

Sustainability and Easy Cleaning

- Low Residue: Typically, no post-cleaning is required as residues are non-corrosive.

- Cleanable if Needed: Can be easily cleaned with warm water or DI water—no special cleaners required.

- Eco-Friendly: Biodegradable and wastewater-treatment compatible, with no negative impact on biodegradation activity.

BECE ENViRE FLUX 8305 combines modern technology with sustainability and reliability, making it ideal for all PCB production requirements.

KEY PRODUCT ADVANTAGES:

- Sprayable and foamable

- Excellent wetting properties, ensures high-gloss and uniform solder surfaces

- Through-holes are effectively filled with solder, even at high speeds

- Reduces surface tension, removes oxide layers, and protects the surface from reoxidation

- 100% water-based

- Halogen-free; contains no chloride, bromide, or fluoride

- 100% free of volatile organic compounds (VOC-free); contains no IPA, methanol, ethanol, or other solvents

- Non-corrosive after soldering, low in solids

- RoHS compliant, passed all tests according to IPC-TM-650 / J-STD-004. Classified as ORL0