You are here:

Home » Products – Electroless Nickel/Gold (ENIG)

Electroless Nickel / Immersion Gold (ENIG)

BECE IMOR-N – Immersion gold plating process for high-quality 24-carat gold layers

BECE IMOR-N is a mildly acidic, immersion gold plating process that deposits thin 24-carat gold layers. With excellent adhesion and superior properties, it delivers optimal results for various applications in PCB and surface technology.

Outstanding Features

- Thin, Uniform Layers: In a displacement process, gold layers up to 0.12 µm are deposited, making it ideal for high-quality final finishes.

- Excellent Adhesion: Forms a perfect bond with chemical nickel layers.

- Superior Functionality: Provides oxidation protection, exceptional solderability, and excellent bonding properties.

Applications

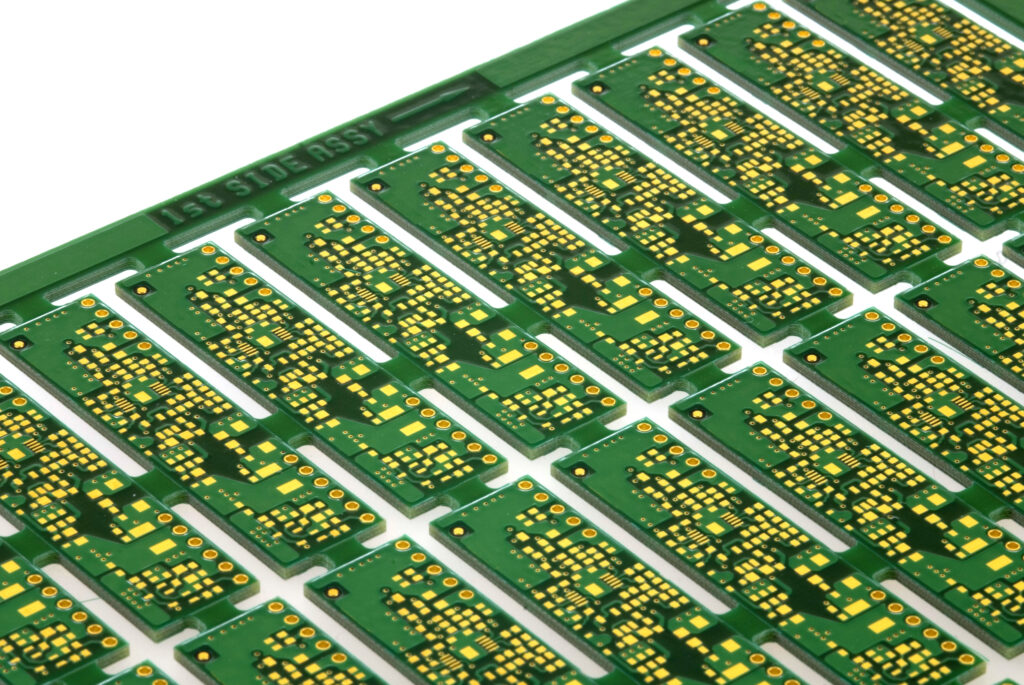

- PCB Technology: Used as a final surface finish for printed circuit boards (ENIG process) with a perfectly tailored process flow.

- Rack and Barrel Plating: Versatile for use in various production methods.

BECE IMOR-N is the ideal solution for achieving high-quality 24-carat gold finishes with outstanding performance in modern manufacturing processes.

KEY PRODUCT ADVANTAGES

- High-quality results: 24-carat gold layers with uniform thickness and strong adhesion

- Reliable performance: Excellent properties for oxidation protection, soldering, and bonding processes

- Flexibility: Suitable for rack and barrel plating

- Efficient application: Precise and easily integrable into existing production processes

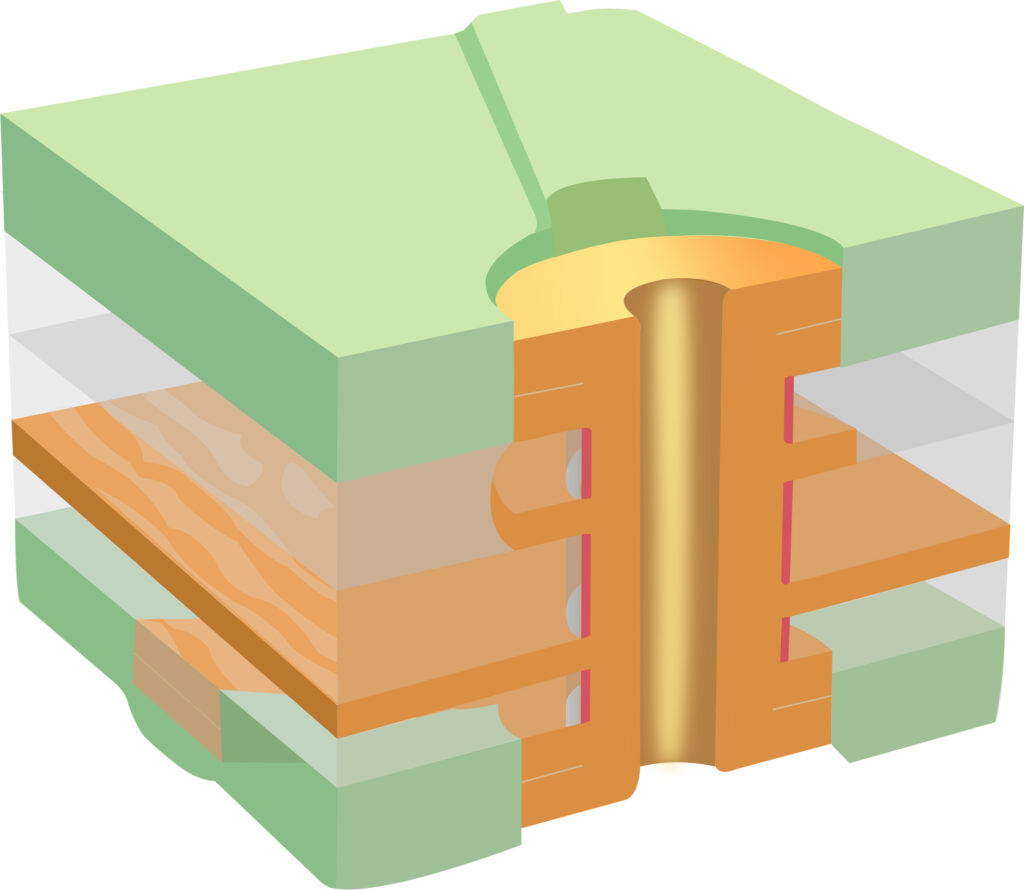

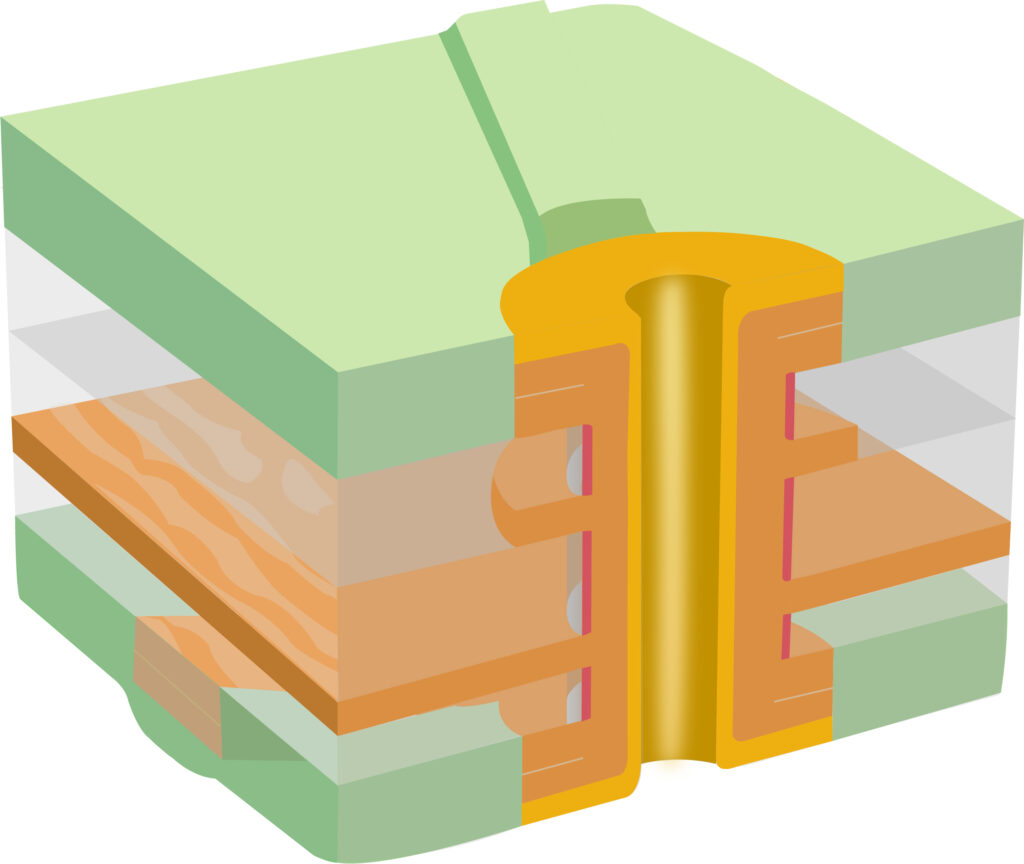

Before and After Visualization:

BECE ENiCOAT-LP 9000 – Electroless Nickel process for high-quality final surfaces

BECE ENiCOAT-LP 9000 – Electroless Chemical Nickel Process for High-Quality Final Surfaces

BECE ENiCOAT-LP 9000 is a reductive electroless nickel process that deposits metallic, glossy nickel layers with superior physical and chemical properties. It is the ideal solution for PCB and surface technology applications, serving as a diffusion barrier between copper and gold.

Outstanding Features

- High-Quality Nickel Layers: Contains 7–9% phosphorus, providing optimal solderability, bondability, ductility, and corrosion resistance.

- Efficient Deposition: Achieves layer growth of 15–20 µm/h, meeting precise production requirements.

- Versatile Application: Suitable for PCBs, catalyzed non-conductors, rack plating, and barrel plating.

Applications

- PCB Manufacturing: Ideal for ENIG processes and demanding surface requirements.

- Surface Coating: Reliable for coating PCBs and non-conductive materials.

Perfect Process Combination

When combined with other BECE processes, it delivers a perfectly tailored solution for ENIG final surfaces:

- BECE Pre-Cleaning: Ensures a flawless surface before nickel deposition.

- BECE IMPA-ACTIVATE NG-S: Palladium activator for a stable conductive layer.

- BECE IMOR-N: Chemical immersion gold process for the final gold layer.

KEY PRODUCT ADVANTAGES

- Excellent layer properties: Metallic gloss, robust, and corrosion-resistant

- Process reliability: Consistent results with high reproducibility

- Flexibility: Suitable for rack and barrel plating as well as various materials

- Efficiency: Fast deposition with optimal phosphorus distribution