You are here:

Home » Products – Electroless copper process

Electroless copper process

BECE IMCU-ECQ – Innovative electroless copper process for the PCB Industry

BECE IMCU-ECQ is a high-performance chemical copper process specifically developed for the metallization of non-conductive materials. It forms electrically conductive copper layers, making it ideal for the through-hole plating of vias and blind holes while meeting the requirements of modern PCB technologies.

The BECE IMCU-ECQ process includes the specially designed colloidal palladium activation BECE IMPA-ACTIVATE, ensuring reliable adhesion and optimizing the entire metallization process. The process consists of four precisely coordinated stages to deliver consistent and high-quality results.

Outstanding Features of BECE IMCU-ECQ

- High Deposition Precision: Ensures a consistent and uniform deposition rate.

- Excellent Layer Quality: Fine-grained, adhesive, and bright copper layers guarantee perfect metallization on base materials and non-conductive surfaces.

- EDTA-Free Formulation: Free from EDTA and complexed with Quadrol, minimizing environmental impact.

- Exceptional Stability: Reliable operation due to outstanding process stability and long service life.

Ideal Solution for Modern Technologies

BECE IMCU-ECQ is versatile and highly suitable for the requirements of SAP technology (Semi-Additive Processing), a key technology in PCB production that enables precise and fine structures.

Flexibility in Application

The process is compatible with both horizontal and vertical systems, ensuring broad applicability across various production environments.

Applications

BECE IMCU-ECQ provides a reliable solution for the metallization of non-conductive materials, excelling in quality and versatility, particularly in advanced technologies such as SAP.

KEY PRODUCT ADVANTAGES

- Highly stable and well-covering electroless copper bath

- Fast-depositing copper process

- No ramp-up time required

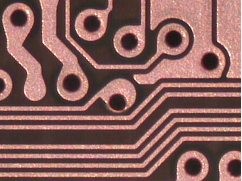

- Even the smallest drill holes are perfectly metallized

- Excellent for use in fine-line technology and semi-additive processes

- Excellent copper adhesion values

- Effective drill hole conditioning system

- Highly effective palladium activation

- EDTA-free

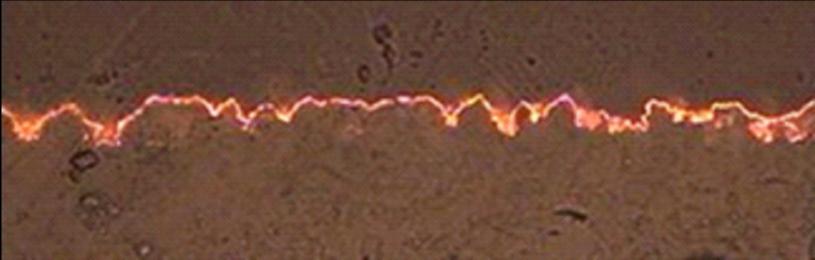

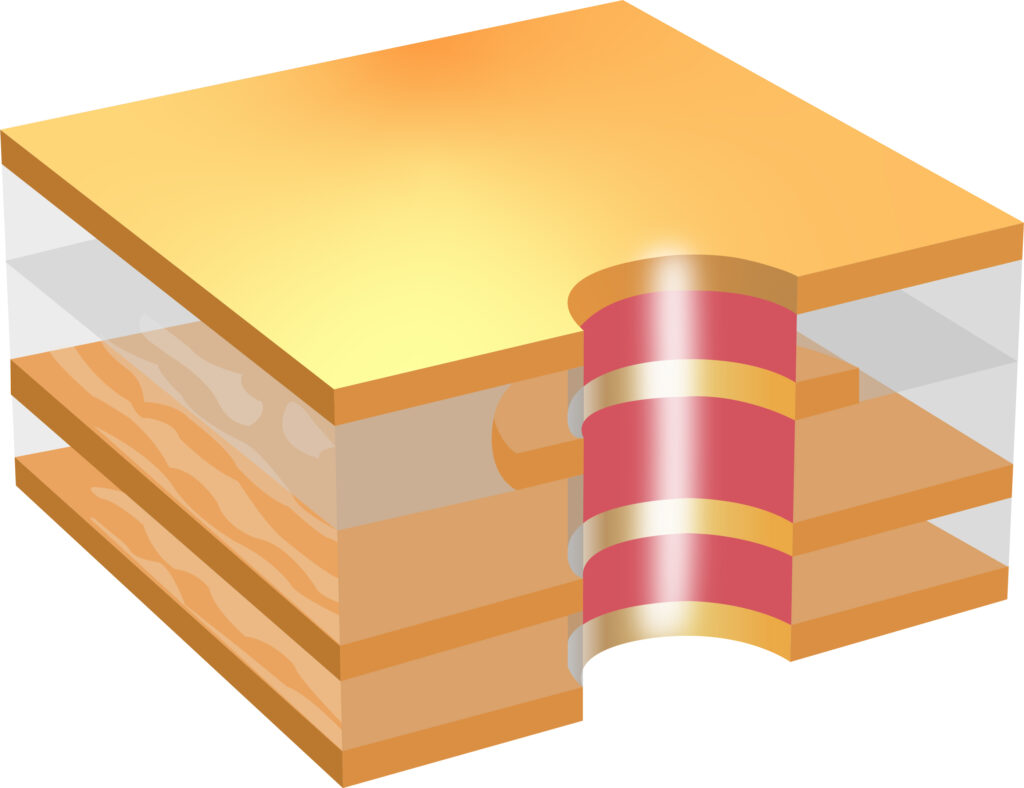

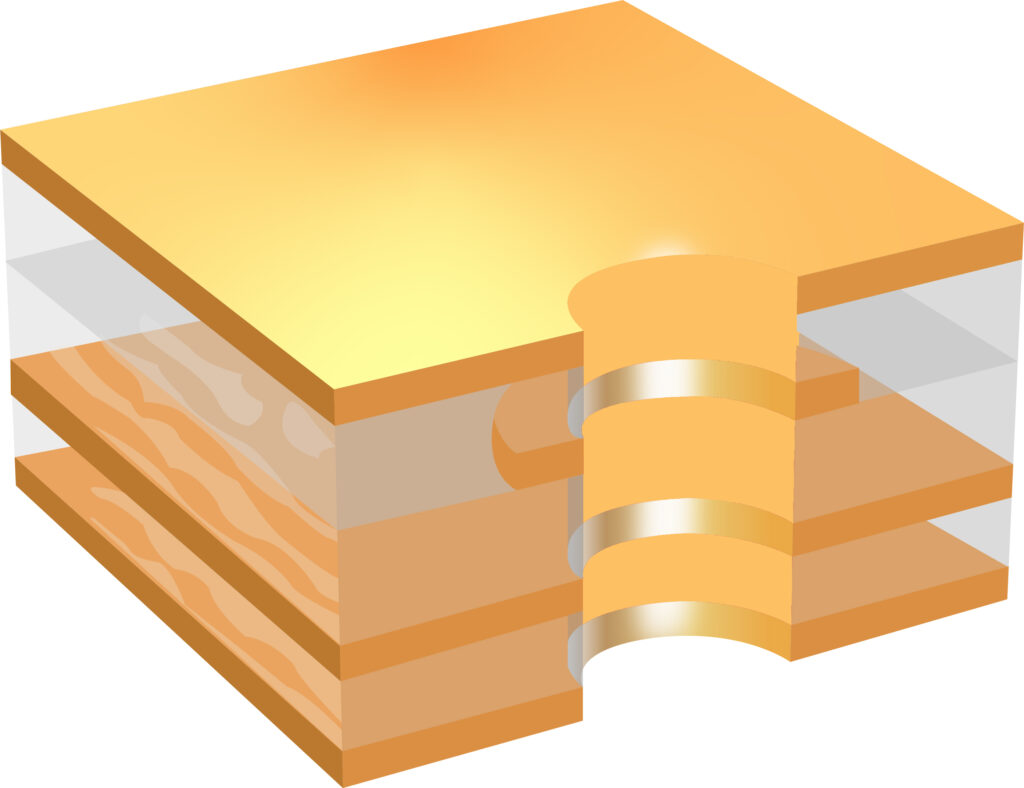

Before and After Visualization:

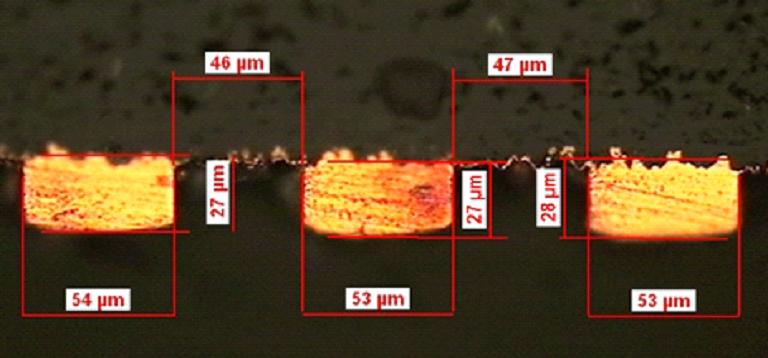

Example of a Semi-Additive Process (SAP):