You are here:

Home » Products – alkaline copper etching

Ammoniacal Copper Etching Process

BECE Highspeed Etch 92 FineLine – Precise and stable etching process for high-quality printed circuit boards.

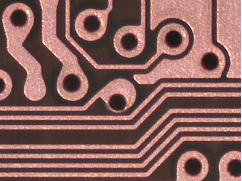

BECE Highspeed Etch 92 FineLine is an alkaline etching process based on ammonia/copper chloride, specifically developed for etching copper. This process is ideal for the production and structuring of conductive tracks on high-quality printed circuit boards, offering high precision and process reliability.

Outstanding Features

- Protection of Tin: The etching process does not attack tin and delivers consistently excellent results across a wide range of production conditions.

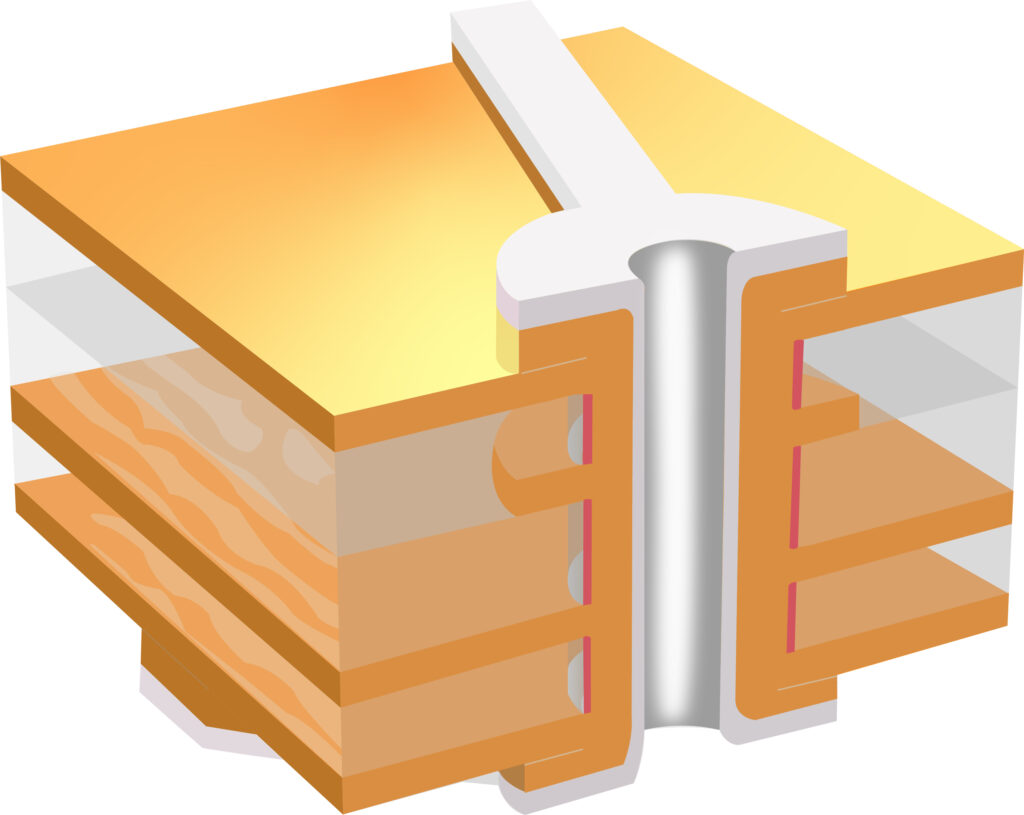

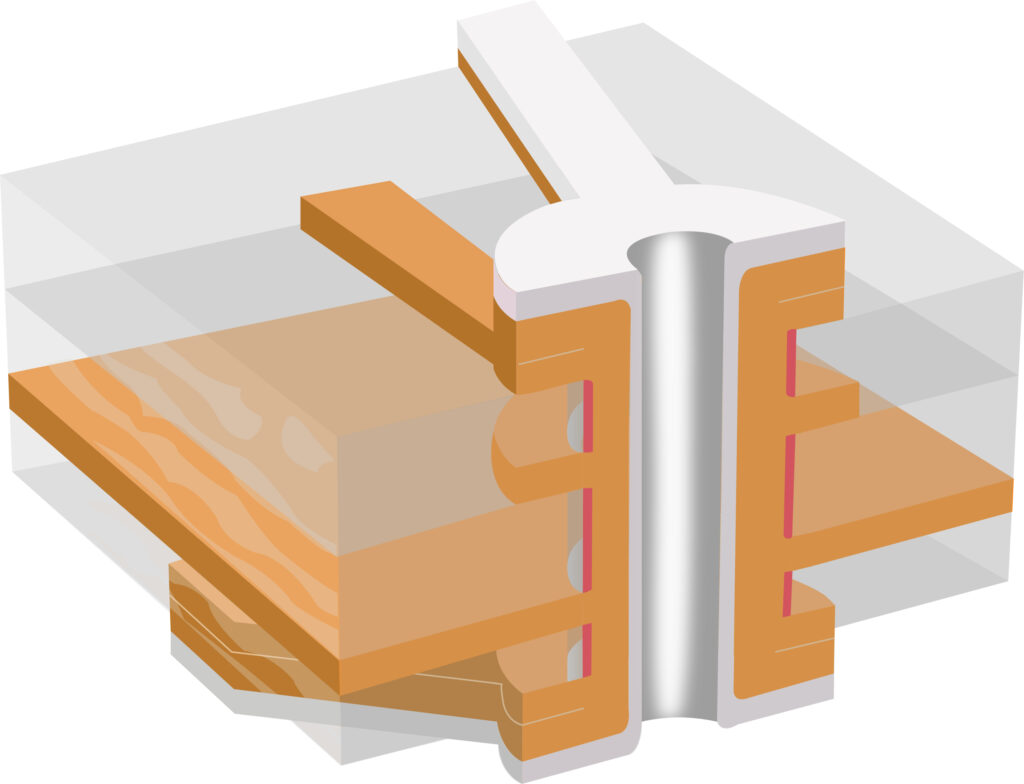

- Stable Etch Rates: Automated etching systems with density-controlled dosing ensure a consistent etch rate and significantly reduce lateral undercutting.

- Preventing Copper Sludge Formation: Stabilized pH buffering prevents the formation of copper sludge, avoiding nozzle blockages and enhancing operational reliability.

Efficient Performance

- High Copper Absorption: Consistently up to 170 g/l, ideal for continuous operation.

- Optimal Etch Rates: Approximately 50 µm/minute at 49°C, with an etch factor of 3:1 to 4:1 in horizontal conveyor systems and spray pressures between 1.5–3.0 bar.

Material Compatibility

In addition to tin as an etch resist, BECE Highspeed Etch 92 FineLine is compatible with alkali-resistant dry film resists and solvent-soluble screen printing inks. Compatibility with alkali-strippable screen printing inks is limited and should be tested beforehand.

Reliable Quality and Cost-Effectiveness

Stringent quality controls and extensive testing ensure consistently high performance. Faster production speeds and reduced machine downtime offset higher costs compared to acidic etching solutions, making this process ideal for precise, reliable, and economical copper etching with maximum efficiency and increased yield per production run.

KEY PRODUCT ADVANTAGES

- High etching speed of approximately 50 µm/minute

- Significant reduction of undercutting

- High etch rate with excellent etch factor

- High copper absorption of up to 175 g/l

- All copper laminations can be etched by adjusting the operating parameters

- Fully automated process (feed and bleed)

Before and After Visualization: